Precision CNC Machining Solutions to Common Plate Work Challenges

High-quality machining services for CNC plate parts are not easy to find. That’s why we decided to hone our plate work machining expertise here at US-based Summit CNC, offering exceptional CNC plate parts that meet all critical specifications.

High-Quality CNC Machining Services for Plate Parts in the US

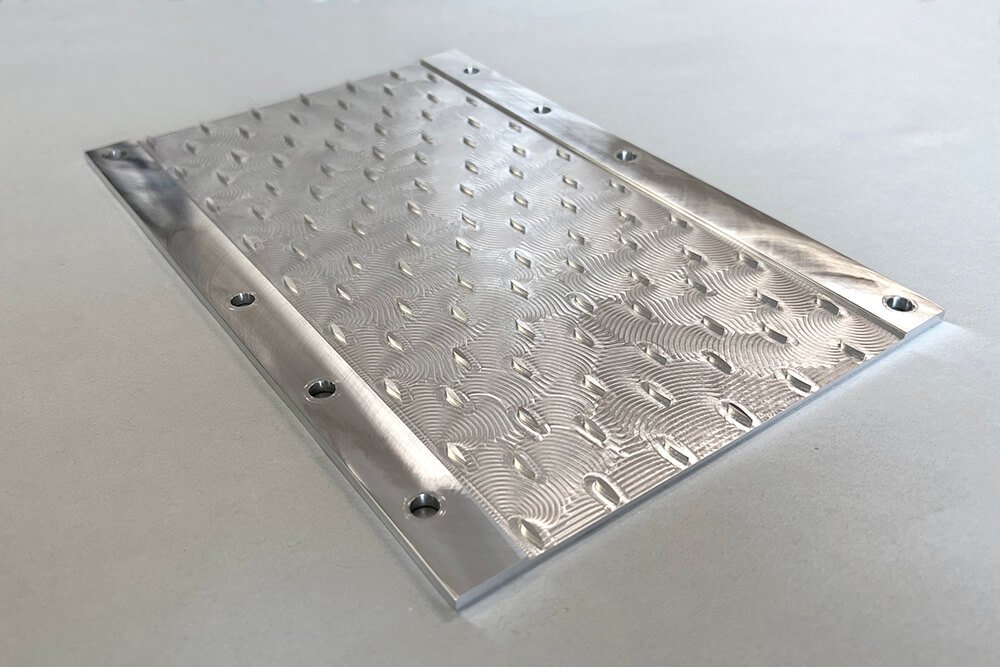

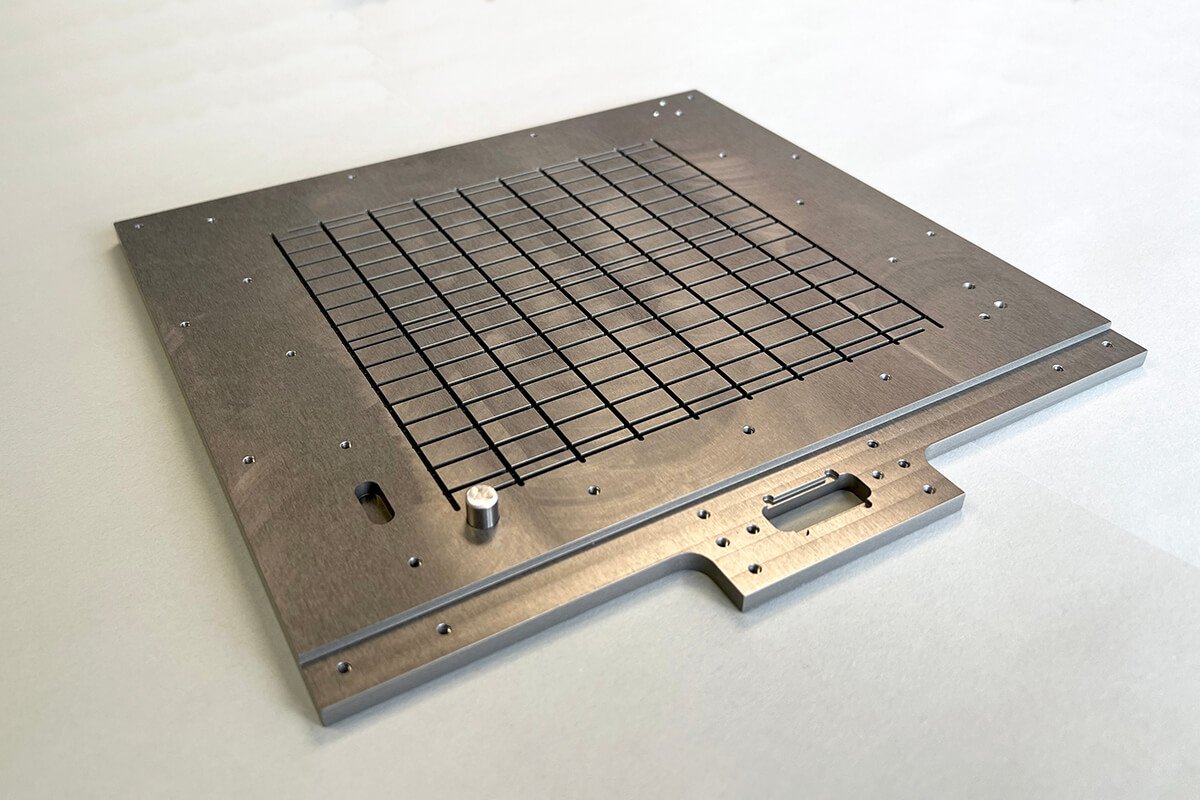

Summit CNC uses plate stock to machine thin parts with large surface areas, such as vacuum plates and thermal hydraulics parts that control the flow of gasses and liquids.

CNC machined plate parts can be made from metals like aluminum, steel, stainless steel, titanium, brass, copper, and many others. We can also machine them from a variety of plastics, including PEEK and Ultem.

Most of the plate parts we machine are for customers in the aerospace, defense, and medical industries, though there are countless applications and industries with CNC plate machining needs.

3 CNC Plate Machining Challenges Our Team Can Tackle

Anyone can purchase plate stock and clamp it in a machine, but not all precision machine shops are equipped to manage the challenges associated with machining CNC plate parts:

1. Scalloping

Because CNC plate stock can be extremely thin, it’s oftentimes prone to bowing when placed in a vise for precision machining. And for any plate stock material thinner than 0.75”, chatter may occur, meaning the material will vibrate during the machining process.

These factors cause scalloping, an unacceptable surface roughness characteristic that can interfere with the part’s functionality. For example, CNC parts intended to form a seal may not be capable of tightly sealing with a mating surface if scalloping has occurred.

2. Inadequate Flatness

Bowed material can also throw a part’s flatness out of tolerance. When machining a bowed surface—even if the curve is slight—the machine tool will cut unevenly, removing more material where the stock is bowed upwards.

As a result, the finished CNC plate part will have a poor flatness tolerance because it is thinner in the areas where more material was removed.

3. Unacceptable Locational Tolerances

Compared to bar stock, plate stock is difficult to clamp evenly. To meet locational tolerances for holes, contours, or other features, additional setups are often required when machining such features.

The plate may need to be re-clamped multiple times to adequately secure the material and achieve each specified tolerance.

How Summit CNC Solves Plate Work Challenges

With the most common plate work challenges identified, Summit CNC developed and implemented fail-proof processes for machining exceptional CNC plate parts.

1. Our Solution for Ideal Flatness and Surface Finish

For each CNC plate part that we machine, we utilize a fully customized workholding method that stops the material from bowing, enabling us to guarantee superior flatness and an exceptional surface finish.

Instead of applying clamping pressure along the material’s Y axis, we mount the plate stock to thick, precision machined workholding plates, securing the material to the firm, flat workholding with either vacuum pressure, clamps and through screws, or a combination of the two.

This sturdy workholding solution ensures that we meet our customers’ flatness specifications and there is no scalloping.

2. Our Solution for Locational Tolerances

The simplest solutions are often the most effective, and this adage proves true for preventing out-of-tolerance locational features in CNC plate parts.

How do we eliminate locational tolerance issues pertaining to holes, contours, and other critical features?

We slow down.

By taking as much time as necessary to effectively place and clamp the plate stock, we’re able to achieve locational tolerances for all of the features on a given CNC plate part.

Ask about our CNC machining services for plate parts at Summit CNC

If you need thin, flat parts, Summit CNC is your go-to precision machine shop.

Reach out to discuss how we’ll tackle your part, or skip ahead and request a quote today!